Root Cause Analysis: Solving Causes, Not Symptoms

Ask The Experts | By | 13 May 2022 | 4 minute read

You’re walking out your door to go to work and as you approach your car you notice a small pool of oil on the driveway. Of all the things you feel like dealing with today, this falls pretty low on the list but you know that if left unaddressed, a small problem could turn into a major catastrophe.

Here’s the thing — addressing problems quickly is important, but doing so effectively is paramount. After checking the oil level in your engine, you top it up, soak up the sticky pool and head for the office. You know, however, in the back of your mind that your problems aren’t over and unless you take further action things could get worse.

A problem isn’t solved until it’s gone for good. Unless you can get to the root cause of the problem, a small pool of oil can turn into a broken down car on the highway on the way to work.

What is a Root Cause Analysis?

A root cause analysis can come in many forms, whether it’s a sophisticated statistical model or a simple conversation, the goal is the same; to identify and eliminate the source of a problem and prevent future problems from reoccurring.

The approach being utilized will depend on several factors, including the availability of reliable data, the type and repeatability of the problem being analyzed, the experience of the problem solver, and the timeframe available to solve the problem.

Problem-Solving Using Root Cause Analysis

There is rarely only one root cause of any problem; usually there are either multiple causes or a confluence of causes interacting with each other to create the problem. A problem’s cause almost never originates at the point where the issue is discovered but somewhere upstream and the reason for discovery is just a symptom of a much deeper problem. The ability to determine the difference between a symptom of the cause and the cause itself is critical for successfully eliminating the problem.

Symptoms Vs. Root Cause

If a car has an oil leak, refilling the oil may get you to your destination but it doesn’t prevent the oil from leaking out again, and you’ll soon find yourself having to add more.

The first step in addressing this problem is to top off the oil, but afterwards, you’ll need to dig deeper to understand why it leaked out in the first place. The leaking oil is not the problem, it is only a symptom of an underlying issue.

As you continue to explore and uncover additional symptoms, you’ll need to take additional countermeasures until you finally arrive at the root cause. Upon further inspection of your leaking oil, you then discover that it was leaking because of a clogged oil filter, so you replace the filter and the leak stops. However, does this mean you have solved the problem?

It’s important to take countermeasures to eliminate the immediate negative impacts, but those countermeasures don’t necessarily fix the problem or prevent recurrence. It’s not uncommon for symptoms to be the causes of other symptoms, which makes it easy for the practitioner to mistake them for the root cause and stop searching before the source is uncovered.

5 Whys Problem Solving

So how does someone know when they’ve eliminated the root cause of a problem versus covering up a symptom? Where do you start and how do you know when to stop?

A simple, practical method comes from an ability that we all seem to have been born with. It’s the act of observing a problem and simply asking, “Why?” again and again, starting at the problem and working your way backwards through the symptoms.

As each “Why” is answered, countermeasures are implemented until the root cause is discovered and eliminated. Generally, after about the fifth why or so, you should arrive at a problem’s cause, although 5 is not a magic number, it may be 3 or it could be 7, but 5 will get you close.

5 Whys in Action

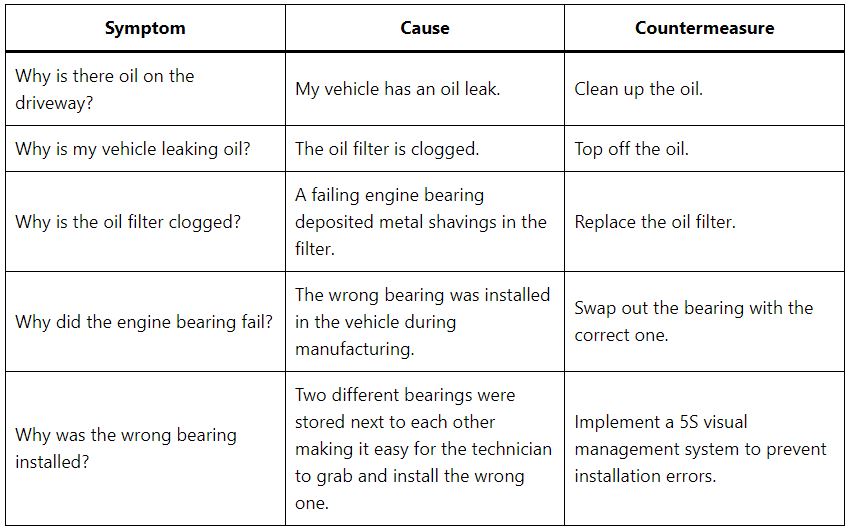

In the earlier example, the cause of the leaking oil was identified to be the clogged filter, but was that the root cause? And if not, how do you know when to stop looking? By utilizing 5 Whys, you’ll be able to quickly find the root cause and the answer to your problem will become obvious.

It will look something like this:

The Problem: Oil Spilled on the Driveway

As you can see, the clogged oil filter was not even close to the root cause of the problem and it was necessary to dig much deeper than originally thought. Typically, you can stop searching for the root cause once you have run out of countermeasures within your control to implement.

But, if this were a situation in which there could be multiple root causes, you would need to ask the same initial question again but then follow a different line of questioning such as, why were the different bearings so easily confused with each other, or why would the wrong bearing be able to be installed in engine to begin with?

5 Whys: The Key to Root Cause Analysis

As you can see, the 5 Whys methodology is simple, requires no training, and can be done at any time. Practice and repetition will make you more effective and efficient at it, so it would benefit the practitioner to look for as many opportunities to apply the tool as possible.

The easiest way to know if you discovered the root cause is to keep an eye out for the problem to resurface, and If it does, simply ask yourself, “Why?”

Important Notice

The information contained in this article is general in nature and you should consider whether the information is appropriate to your specific needs. Legal and other matters referred to in this article are based on our interpretation of laws existing at the time and should not be relied on in place of professional advice. We are not responsible for the content of any site owned by a third party that may be linked to this article. SafetyCulture disclaims all liability (except for any liability which by law cannot be excluded) for any error, inaccuracy, or omission from the information contained in this article, any site linked to this article, and any loss or damage suffered by any person directly or indirectly through relying on this information.