When evaluating the quality of a product or service, what exactly is being measured? Is it functionality, fit and finish, or its ability to delight a customer?

Depending on the context, the word quality can be either a relative or absolute concept. From a relative value standpoint, if something exceeds the expectations of the customer for the price they paid, it may be considered a quality product. However, compared to similar products of superior design or performance, that same product may be considered of inferior quality.

In the absolute sense of the word, a product or service that functions as designed and performs as intended could be considered of high quality regardless of the customer’s perception.

In some cases, something is of high quality only if it goes completely unnoticed. It is the old offensive lineman analogy in football: “You only notice it when something goes wrong, but if it is doing its job, it is invisible.” People do not feel relief every time they hit a switch and the light turns on—as it is supposed to. Instead, they only notice when it doesn’t.

In these cases, the consumer’s expectation is that the product will work as advertised for its intended purpose, and meeting that expectation won’t really impress anyone.

Definition and perspectives of quality

The godfather of quality Edward Deming, I believe rightfully, stated that the customer’s definition of quality is the only one that matters. Although that is true, it does not really help define what it is.

What if customers have conflicting definitions for the same product? If a customer is not fully qualified to define the quality of a product, should all definitions be considered equally? Notice Demming did not say that a customer’s definition is the only one, but just the only one that matters.

Assuming Demming is right, which you should, it is incumbent upon producers and service providers to understand, as quantifiably as possible, the expectations of their customers and how their product or service compares relative to the competition. For instance, in electronic manufacturing, the use of conformal coating is a critical consideration. This coating, which protects electronic components from environmental factors such as moisture and dust, exemplifies how meeting specific technical requirements can influence customer perceptions of quality. This attention to detail in the development phase contributes significantly to a positive product experience, as it helps prevent potential issues related to component failure or degradation. By ensuring that products are protected and perform reliably under various conditions, companies can better meet customer expectations and differentiate themselves from competitors. It is also necessary to have a quality improvement process in place to measure whether or not customer expectations are being met and be able to detect any shifts in customer expectations in real-time. To support these continuous improvement efforts, organizations can seek business grants aimed at encouraging innovation, quality assurance, and process optimization.

At the same time, a delicate balance must be struck to ensure that products and services are not being over-engineered and exceeding customer expectations by too much. A little bit is okay, but if you go overboard, you will eat into your profits unnecessarily.

Overprocessing is one of the eight great wastes of Lean and results in companies incurring costs for features the customer sees no value in. The trick in all of this is for a company to figure out the sweet spot where they slightly exceed customer expectations and maximize perceived value without spending time or money on features the customer would pay the same amount for even if those features were removed.

The role of quality in short-term profitability and longevity

The founder of modern business management, Peter Drucker, once famously stated, “Because the purpose of business is to create a customer, the business enterprise has two—and only two—basic functions: marketing and innovation. Marketing and innovation produce results; all the rest are cost.”

My question would be, where does quality fit into this equation? For this statement to be correct, a few assumptions must be made.

First, if Drucker is speaking about long-term profitability, the innovation he is referring to must align with Demmings’ contention that the customer defines quality for a good or service. A product can be supremely innovative, but if it falls short of or too far exceeds customer expectations, any profits will be short-lived. To align with evolving customer expectations, businesses must not only innovate but also enhance their customer interactions. Evaluating and adopting the best softphone solutions can play a crucial role here. These tools improve communication efficiency, support high-quality customer service, and ensure that businesses can meet and adapt to changing customer needs effectively.

Secondly, for marketing to be effective, a company must understand the customer’s definition of quality and value and communicate how their product provides that value.

Using an email finder tool in conjunction with an email verifier, a company can gain valuable insights into its target audience, which can improve the effectiveness and email deliverability of its email marketing campaigns. Platforms like mailmodo help businesses take this a step further by enabling interactive, intent-driven emails that align communication quality with customer expectations, making value delivery clearer rather than just louder.

By focusing on email design as well, businesses can create visually appealing and user-friendly campaigns that highlight the quality and value of their products. To reduce the risk of landing in the spam folder while, at the same time, increasing engagement and ensuring perfect inbox placement, companies can use a warm-up email to enhance email deliverability. Companies also have the option to enlist the expertise of professional email marketing services to execute their campaigns.

Finally, given that customer expectations change over time and thus so does the definition of quality, marketing efforts must successfully detect those changes and innovations must meet the new standard. For engineering teams that are constantly innovating, identifying tools like contact center software that seamlessly align with their workflow is crucial. Take CAD software – comparing Fusion 360 vs Onshape could yield significant insights for product development processes. It is at that point that the cycle repeats.

Quality improvement for long-term gains

Philip Kolter—marketing author, consultant, and professor—defines marketing as “the science and art of exploring, creating and delivering value to satisfy the needs of a target market at a profit.”

This definition seems to support both Drucker and Demming’s assertions, assuming the concepts of value and quality are closely related. Once explained in this context, it is easy to see the critical role quality plays in a company’s short-term profitability and long-term survival.

Drucker also stated that—and I am paraphrasing—what made a company successful in the past is not going to make it successful in the future and that a company must constantly innovate to survive. Therefore, a leading indicator of long-term survival is measured by a company’s ability to improve quality. By that I mean, its ability to:

- efficiently and effectively detect changes in customers’ ever-evolving definitions of value and quality

- align product innovations with those changes

- communicate those changes back to the market so they understand the value

Quality improvement strategies often intersect with specialized marketing approaches tailored to distinct industries. For law firms, maximizing quality in client engagement and service delivery can go hand-in-hand with data-driven campaigns. Innovative legal marketing services empower legal practices to better meet evolving client expectations, demonstrate value, and ultimately boost ROI—key components for maintaining a competitive edge in today’s fast-changing landscape.

Improving quality through lean tools

Demming and Shewhart’s continuous quality improvement process provides the underpinning for effectively accomplishing this.

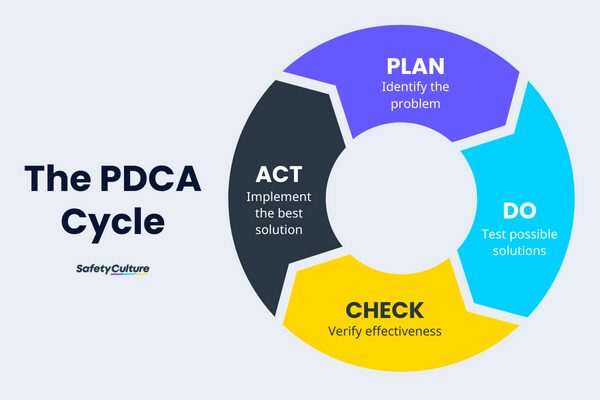

Also known as the Plan-Do-Check-Act (PDCA) cycle, this approach to innovation, problem-solving, and continuous improvement has been the driving force behind profitable business longevity for decades, whether intentionally or by chance.

Based on the scientific method, PDCA takes a logical, objective, and iterative approach to improving processes and aligning with customers’ ever-changing definitions of quality. Although simple in design, it takes discipline and dedication from management to put this methodology into practice.

When combined with the vast array of quality improvement tools, the return on that investment of time and effort will yield the profits Drucker promises when marketing and innovation are aligned with quality.

In practice, quality improvement process steps look something like this:

Plan

- Identify the customer and their definition of value and quality.

- Baseline the product or service’s current performance in relation to the customer’s expectations.

- Quantify the gap and the causes for it.

- Develop a plan to close the gap between expectations and the current state.

Do

- Execute the plan.

- Do so in short intervals.

Check

- Measure the results.

- Learn from the cause-and-effect relationship between the actions taken and the results achieved.

- Remeasure the gap.

Act

- Act based on what was learned.

- Make necessary adjustments.

- Communicate the changes.

Many positive outcomes will be realized by developing a quality improvement plan and practicing PDCA, but perhaps none more powerful than the knowledge that will be gained by better understanding the cause-and-effect relationships between actions and results and the dynamic nature of customer expectations. For this reason, the PDCA cycle should be performed in short intervals to keep up with the speed of change.

Getting started with quality improvement

The best place to start a quality improvement initiative is either with a new product that has recently launched or is about to launch or with a legacy product that has seen stagnant or declining market share. For instance, instead of selling custom Christmas merch from last year’s lineup, a POD business should launch a new lineup with updated designs.

Ask yourself if you truly understand the customer’s expectations and if your product meets them. Does your feedback loop effectively capture and keep up with the changes in the marketplace? Are the right people aware of your product and the value it provides?

Finally, always remember: if you are not innovating, I guarantee someone else out there is, and you will find yourself falling behind if you don’t act now.

Important Notice

The information contained in this article is general in nature and you should consider whether the information is appropriate to your specific needs. Legal and other matters referred to in this article are based on our interpretation of laws existing at the time and should not be relied on in place of professional advice. We are not responsible for the content of any site owned by a third party that may be linked to this article. SafetyCulture disclaims all liability (except for any liability which by law cannot be excluded) for any error, inaccuracy, or omission from the information contained in this article, any site linked to this article, and any loss or damage suffered by any person directly or indirectly through relying on this information.