5 Powerful Stats on Road Worker Safety

Industry Trends | By | 24 Mar 2016 | 6 minute read

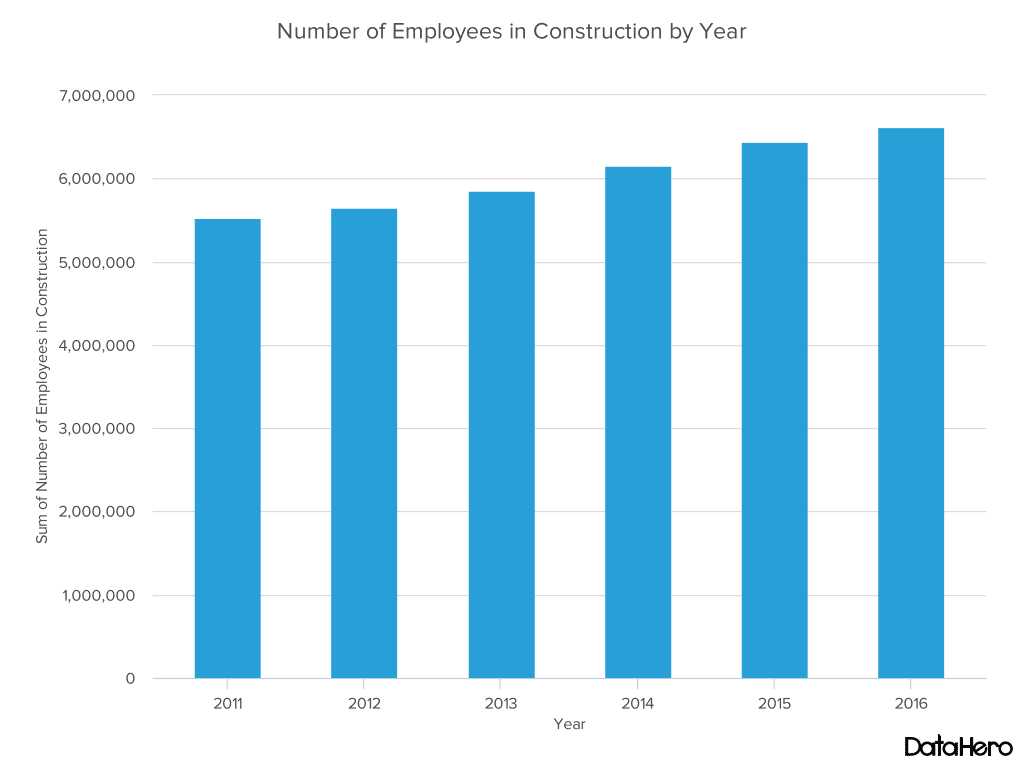

As spring approaches, now is the time to start reevaluating your road construction safety plans and procedures for the upcoming increase in road construction initiatives in 2016. 2015 saw a record high in roadway construction in the US, with an expectation that construction in 2016 will only grow thanks to an increasing number of miles traveled by American drivers. As you’re reviewing and updating your safety initiatives for this spring, use a data driven approach to understand where you need to focus safety efforts and what to communicate to your team to keep them safe. You’ll also get a glimpse at the technology that is aiming to improve these stats, and learn how you can implement it in your company. First a quick bonus data point, note in the chart below how quickly the number of employees in the construction industry has grown in the past five years. This means a large number of new road construction workers will be indoctrinated into your safety processes and procedures this spring. Thus, safety training will require particular effort to ensure best practices are established from the beginning and maintained throughout any road construction project. Of course the ultimate goal is to keep workers safe from injury or worse, but when companies place a premium on safety, they also frequently find that it benefits their budgeting and project management as well.  The number of employees in construction this year will approach 7 million and according to the US Department of Transportation, more than 20,000 road construction workers will be injured each year in collisions. [Tweet “The number of employees in construction this year will approach 7 million in 2016.”]

The number of employees in construction this year will approach 7 million and according to the US Department of Transportation, more than 20,000 road construction workers will be injured each year in collisions. [Tweet “The number of employees in construction this year will approach 7 million in 2016.”]

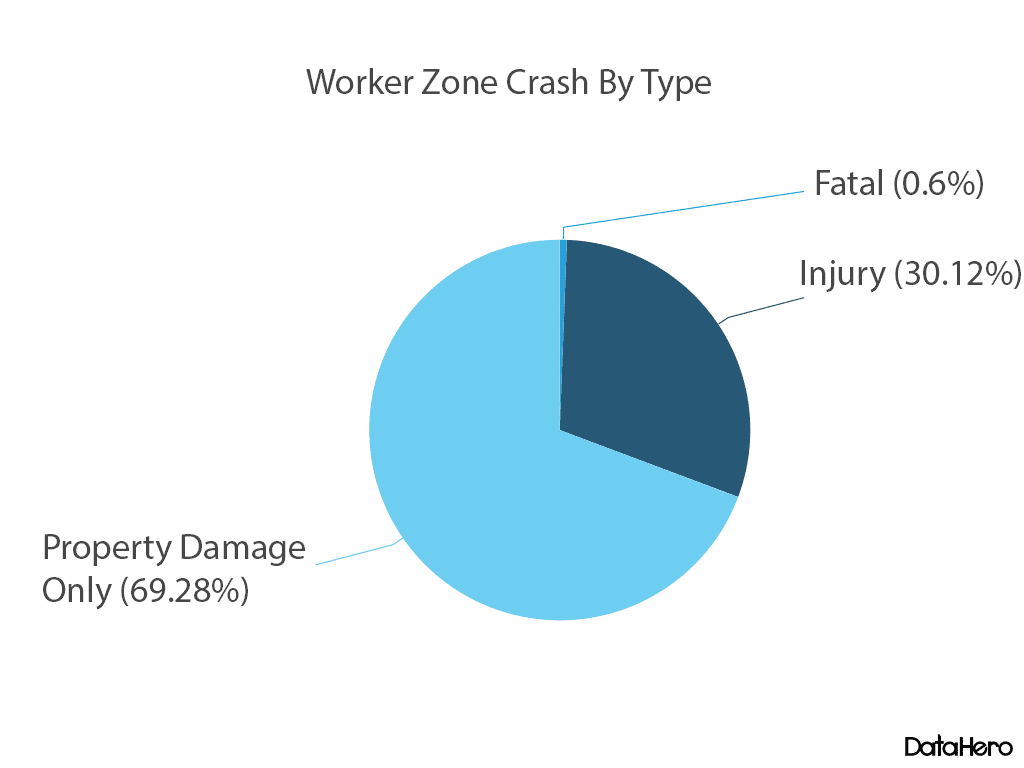

Worker injury or fatality make up about 31% of all work zone collisions

Those 20,000 injuries per year make up about 30% of all work zone collisions, with the majority of work zone crashes resulting in property damage.  Of course property damage is costly and can be time-consuming to address, but the real issue in the chart above, and the main focus for road workers is the 31% of collisions that result in a worker injury or fatality. With 0.6% of work zone collisions resulting in fatalities, we can see how road workers could potentially fall into the trap of believing that a fatal incident could not occur in their work zone, or to their team. This is the allure of complacency and also explains why so many road work incidents occur later in a project, once workers start feeling comfortable. To avoid that sort of complacency, communicate these data points to road workers and keep them top of mind in your safety training.

Of course property damage is costly and can be time-consuming to address, but the real issue in the chart above, and the main focus for road workers is the 31% of collisions that result in a worker injury or fatality. With 0.6% of work zone collisions resulting in fatalities, we can see how road workers could potentially fall into the trap of believing that a fatal incident could not occur in their work zone, or to their team. This is the allure of complacency and also explains why so many road work incidents occur later in a project, once workers start feeling comfortable. To avoid that sort of complacency, communicate these data points to road workers and keep them top of mind in your safety training.

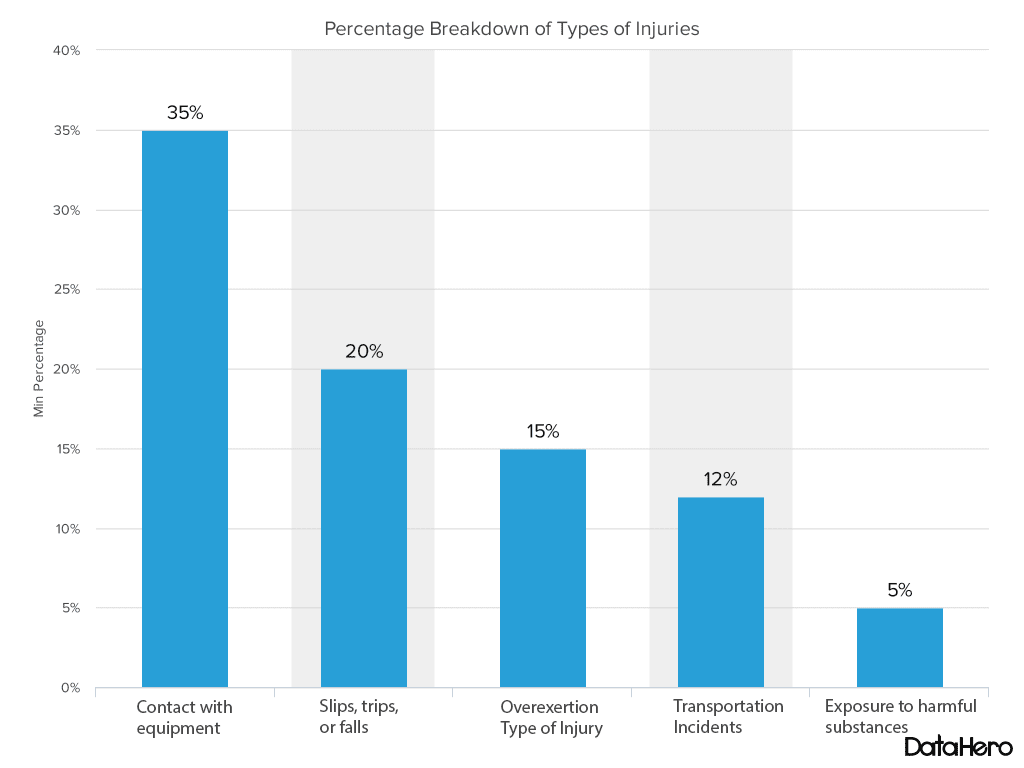

Top worker injuries on a road construction site

In the chart below we see the percentage breakdown of the top five most common work zone injuries.  Please note that the 13% of injuries marked as “Other” have been removed from the chart above for clarity. Contact with equipment is the highest cause of work zone injury, again suggesting that complacency could be in play here. Emphasize proper communication amongst teams and take a look at your equipment training procedures as well to try to reduce this stat on your site. Unfortunately injuries are not the worst incident that can occur on a road construction site. There were 514 fatal collisions in a road construction work zone in 2010. Here’s what you need to know about fatalities in the work zone.

Please note that the 13% of injuries marked as “Other” have been removed from the chart above for clarity. Contact with equipment is the highest cause of work zone injury, again suggesting that complacency could be in play here. Emphasize proper communication amongst teams and take a look at your equipment training procedures as well to try to reduce this stat on your site. Unfortunately injuries are not the worst incident that can occur on a road construction site. There were 514 fatal collisions in a road construction work zone in 2010. Here’s what you need to know about fatalities in the work zone.

The most common cause of work zone fatalities is a result of construction collisions not civilian collisions

Though a lot of attention has been focused on communicating the presence of workers and variable speed limits to passersby, the most common type of work zone fatalities from collisions is not the result of a civilian vehicle striking a road construction worker. The most common fatal collision is due to runovers and backovers with the construction equipment. As previously mentioned, there is also no substitution for work zone best practices such as: having a spotter available at all times to communicate location of workers to drivers with low visibility, high visibility clothing worn at all times, and making eye contact before moving in any direction in a work zone.

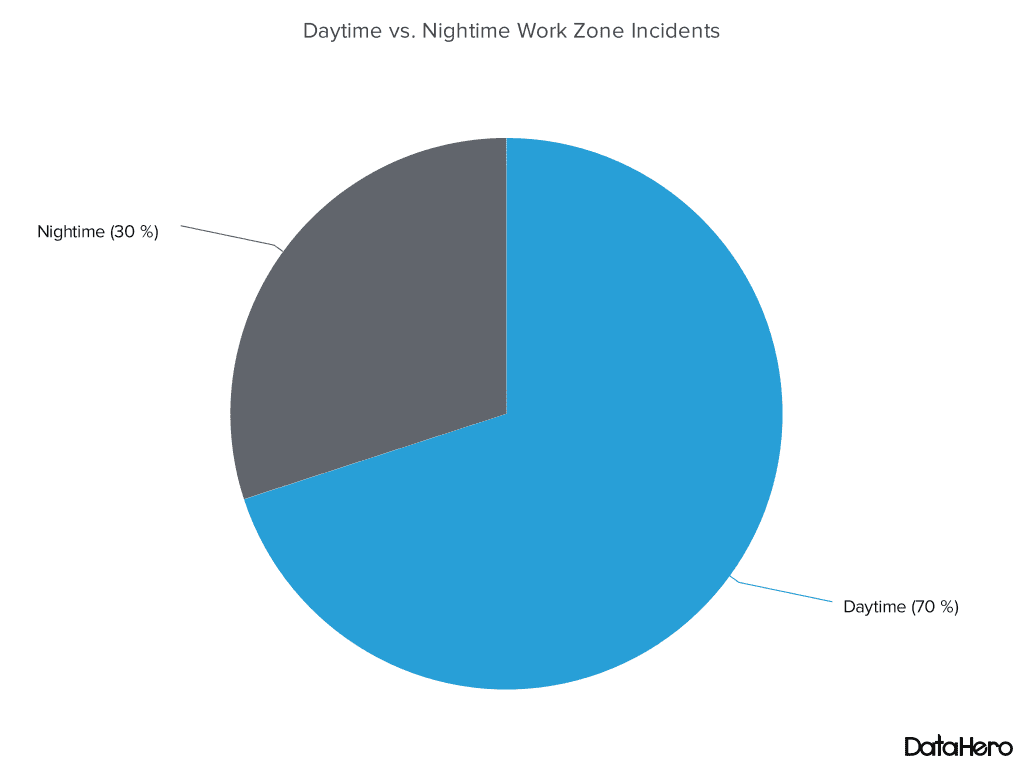

Most collisions occur in the daytime

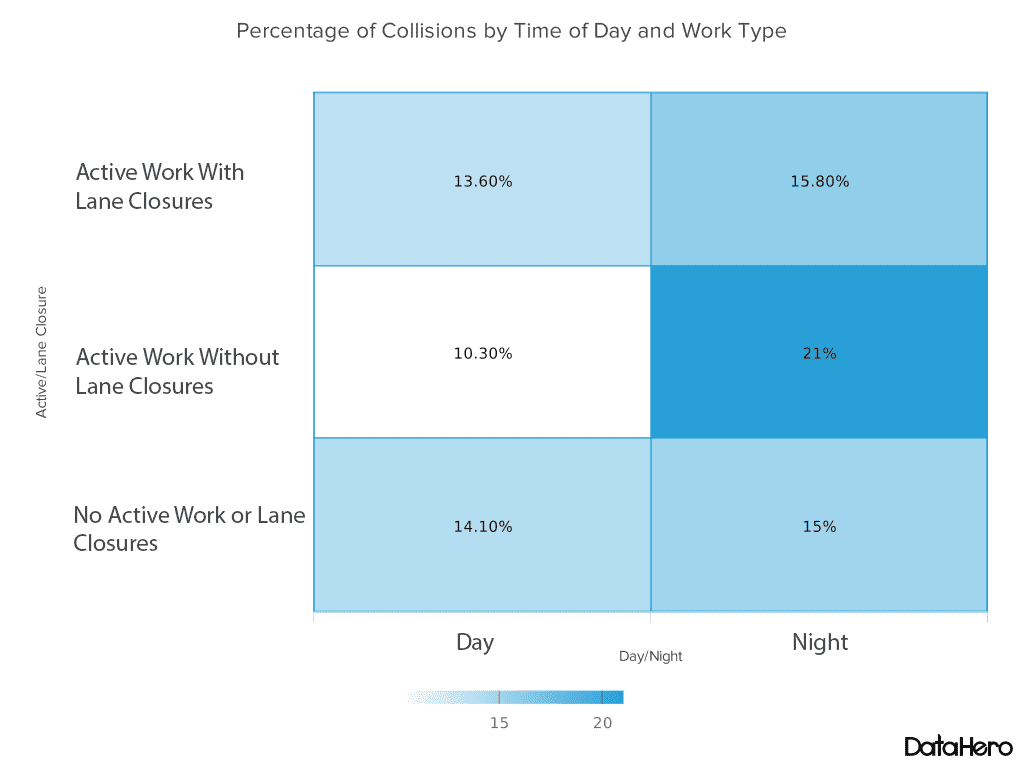

Because of the inherent low visibility associated with nighttime construction, one would assume that it’s a time of higher risk for roadside workers. However, an astonishing amount of incidents occur during daylight hours, as the chart below indicates.  One thing to note is that when we break this data down a bit more by collision types, we can see that the risk for nighttime collisions is slightly higher in many situations, except for rear-end crashes.

One thing to note is that when we break this data down a bit more by collision types, we can see that the risk for nighttime collisions is slightly higher in many situations, except for rear-end crashes.  Rear-end crashes are far more likely to occur in the daytime, with every other sort of collision occurring more frequently at night. Again, the best way to maintain a safe environment and avoid rear-end collisions is to follow outlined safety procedures for drivers such as: dedicating full attention to the roadway and maintaining a safe following distance. As construction technology advances, we’ll start seeing alert systems that bring approaching objects to the attention of the driver.

Rear-end crashes are far more likely to occur in the daytime, with every other sort of collision occurring more frequently at night. Again, the best way to maintain a safe environment and avoid rear-end collisions is to follow outlined safety procedures for drivers such as: dedicating full attention to the roadway and maintaining a safe following distance. As construction technology advances, we’ll start seeing alert systems that bring approaching objects to the attention of the driver.

Construction spend on IT (especially mobile) will increase in 2016

To take advantage of technological advances in safety, the construction sector experts report that they are planning to invest more heavily in IT in 2016, particularly in mobile devices. 41% of firms plan to increase their IT spend in 2016, while 83% say they are currently using mobile devices and 56% plan on implementing mobile software in 2016. This means that in order to stay competitive in the industry, small and large firms alike need to focus on updating IT systems and implementing widespread solutions both in the field and in the office. The use of these mobile devices and streamlined IT systems allow frontline road workers to share their safety audits and reporting processes, noting where hazards exist and preventing any incidents from occurring. Mobile implementation isn’t the only investment in technology in the construction industry, here are some of the other tech trends in road construction. [Tweet “41% of construction firms plan to increase their IT spend in 2016.”]

The future of road safety is closer than you think

Technological developments in road construction safety hinge on three main tenets:

- optimizing construction zones before they’re created

- communication the location of drivers to workers

- improving equipment functionality

Optimizing construction zones

To work on optimizing the safety of a construction zone, the UK Highways Agency has implemented rapid deployment of Speed Check Services. This system can compile traffic speed and location data in order to assess the impact of roadworks in easily-understandable visualization. This allows the construction managers to see where incidents are most likely to occur as a result of civilian traffic and heighten safety measures in an effort to counterbalance that increased risk. It can also track optimal times of day for certain procedures based on traffic flow.

Enhancing communication

Traditionally, communication between road construction workers and drivers has been one-way, and rather passive. Road workers erect signs indicating that a work zone lies ahead with variable speed limits. However, with the proliferation of wearables, the communication can be enhanced and become more two-way. In fact, Sweden has already introduced e-Road Safety (ERS) in many of their highways. ERS acts as a warning system for road workers, identifying the location of personnel and will eventually be able to identify the location of equipment as well. It uses radar units to measure the speed and type of vehicle approaching a work zone and if it’s approaching too quickly, the system alerts the workers with vibrations on an armband or back strap. Germany has also invested four years and millions of dollars into what they’re calling “car to x” communications in their Safe and Intelligent Mobility Testfield (SIM-TD) project. It concluded in 2012 and was successful enough that German vehicle manufacturers, both on the consumer and industrial side, have started equipping their new vehicles with the needed technology in 2015.

Advancing equipment

This kind of “car to x” communication is not only crucial in reducing the number of collisions between civilian vehicles and on-foot road workers, but also could be applied to construction equipment itself in alerting drivers within the work zone to the presence of other road workers in their vicinity, improving equipment functionality. What all these trends suggest is that much of the responsibility and power to keep workers safe rests in the hands of workers. This is particularly impactful as they already have the expertise to understand the pivotal role of safety in their workplace. They know that in order to have all their colleagues return home to their families each day, they need to make safety the focal point of each project. This is why providing them with the proper tools and training this spring is so important to laying the foundation for a safe and productive 2016 ahead. Take a look at how one road construction company was able to use a mobile auditing app to improve communication with clients, track progress and ultimately lead safer projects. NA Road Group, the road construction company, saves “1,500 man hours per year” and claims that with “half the effort we used to put into paper [we’ve] become a lot more organized”. Watch the full case study below to learn more.

Important Notice

The information contained in this article is general in nature and you should consider whether the information is appropriate to your specific needs. Legal and other matters referred to in this article are based on our interpretation of laws existing at the time and should not be relied on in place of professional advice. We are not responsible for the content of any site owned by a third party that may be linked to this article. SafetyCulture disclaims all liability (except for any liability which by law cannot be excluded) for any error, inaccuracy, or omission from the information contained in this article, any site linked to this article, and any loss or damage suffered by any person directly or indirectly through relying on this information.