National Safe Work Month: Everyone Deserves To Go Home Safe Each Day

Industry Trends | By | 5 Oct 2016 | 3 minute read

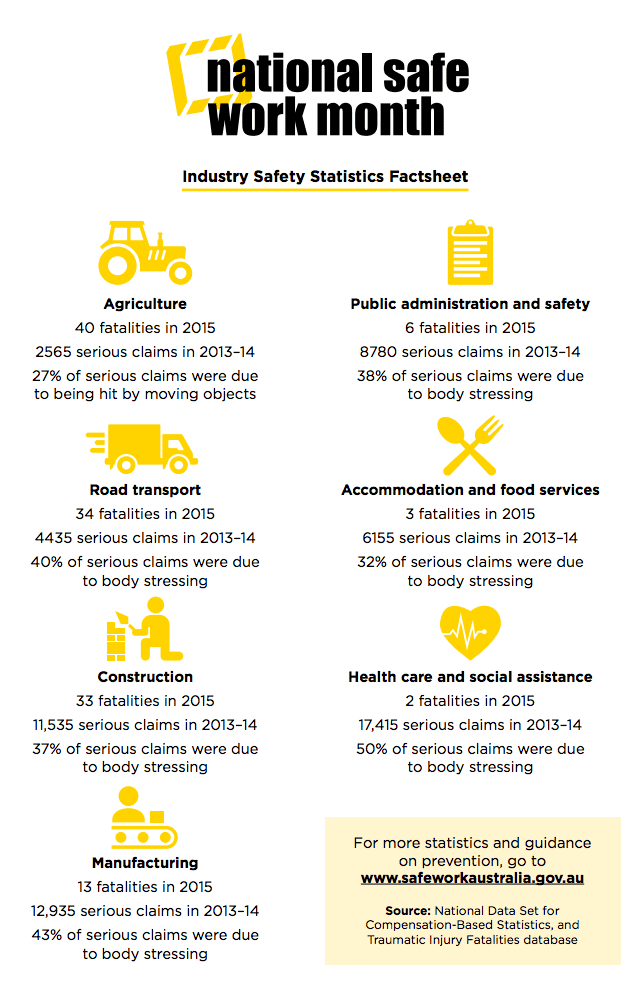

Every year 260 Australians die as a result of work-related injuries. In addition over 135,000 get injured. That figure is even higher in the United States. Safe Work Month is during October each year in Australia. It’s a month to commit to improving work health and safety. And to remember the most important reasons for staying safe at work.

As a company, we are marking safety and quality less reactive and more proactive. Our customers are performing over 1 million inspections every month using SafetyCulture iAuditor. Front-line workers are driving this change. They are on their way to higher quality workplaces. Safety and quality relies on a reactive approach. Due to an incident occurring, the government creates policies. As a result the policy gets pushed down to management. Management then push the policy down to frontline workers. There’s a way to avoid the first incident in the first place. We can empower workers to manage safety.

The smartphone is turning the safety industry on its head. Making low-cost safety management available to everyone. The statistics below paint a picture of why workplace safety is so important.

How our customers are helping their workers stay safe

Just like us, our customers commit to improving the quality of their workplaces. Through daily inspections and checks. We have some outstanding people using SafetyCulture to increase workplace health and safety. Each of them help their workers go home safe each day.

Conrad from Level 10

Conrad from Level 10 lived through one incident that changed his outlook on safety. He saw a man drown while on duty. After this incident, Conrad pursued a career in safety management. Many construction professionals undervalue safety procedures. No one thinks a traumatic event could happen to them. The experience of losing a colleague helped him understand the purpose of safe work practices. You can read more of Conrad’s story

Andrew from Goldcorp

Goldcorp, based in Canada, works in one of the most dangerous industries in the world; mining. The hazards underground are real and ever-present. Workers become exposed to many risks. Cave-ins, explosions, vehicle collisions, and crush injuries are all potential incidents. Andrew Johnston is a Goldcorp Safety Officer. His mantra is that safety is the first thing workers talk about at the start of the day. And the last thing they talk about before they go home.

Damien from Orora Group

Damien Kelly is from Orora’s Rocklea fibre packaging plant in Australia. He recently won a Safety Hero Award. Damien is making it easier and faster for workers to complete audits and send reports. In doing so, he’s improving the safety and efficiency of their work environment. Damien treated injuries as a first aid officer over 12 years. He realises that prevention is much better than a cure. He found a love for health and safety in the process.

Stephen from BOC

Stephen Shield, BOC Production Manager and award winner of the WHS Achievement Award. He works with chemical, bulk gases and heavy machinery on a daily basis. It is crucial in his industry to maintain regular checks and have a unified system to keep tabs of it. Stephen’s workplace displays hazards found on large television screens onsite. This is to ensure they get addressed. In increasing reporting, it has boosted site safety.

Joshua from NA Civil Group

NA Civil Group value safety above all else. Using SafetyCulture iAuditor is central to that. Joshua Philpott is the NA Group Safety Officer. He says there is a constant threat of danger on a roadworks site. Particularly at night with fast moving vehicles passing.

Get involved in National Safe Work Month by clicking here. Do you have an story that affected how you view safety that you’d like to share? Tweet us at @SafetyCultureHQ

Important Notice

The information contained in this article is general in nature and you should consider whether the information is appropriate to your specific needs. Legal and other matters referred to in this article are based on our interpretation of laws existing at the time and should not be relied on in place of professional advice. We are not responsible for the content of any site owned by a third party that may be linked to this article. SafetyCulture disclaims all liability (except for any liability which by law cannot be excluded) for any error, inaccuracy, or omission from the information contained in this article, any site linked to this article, and any loss or damage suffered by any person directly or indirectly through relying on this information.