6 Ways To Ace Your Next OSHA Inspection

Industry Trends | By | 8 Nov 2016 | 4 minute read

Federal and state agencies conduct nearly 100,000 inspections each year. The odds of them visiting might be low. However, high quality and safe workplaces make more productive environments for your workers. Not to mention, it keeps them safe too. There’s a lot at stake when an inspector from OSHA visits your workplace. Therefore, taking the necessary steps beforehand can save you time and effort when the inspector knocks on the door.

Former OSHA assistant area director, Rick Kaletsky cites a case where a young employee had a number of fingers severed by an unguarded chain on a food processing machine. Kaletsky says there were a variety of things that could have happened to cause this incident. But many were quick to blame the young employee. However, it wasn’t a case of the employee removing the guard – it was unguarded. It’s a mistake to ignore unsafe conditions as OSHA’s legal power can be costly and unpleasant.

It’s up to you to prepare. Here are 6 ways to make sure you’re ready to ace that pending OSHA inspection.

1. Make sure your auditing process is top notch

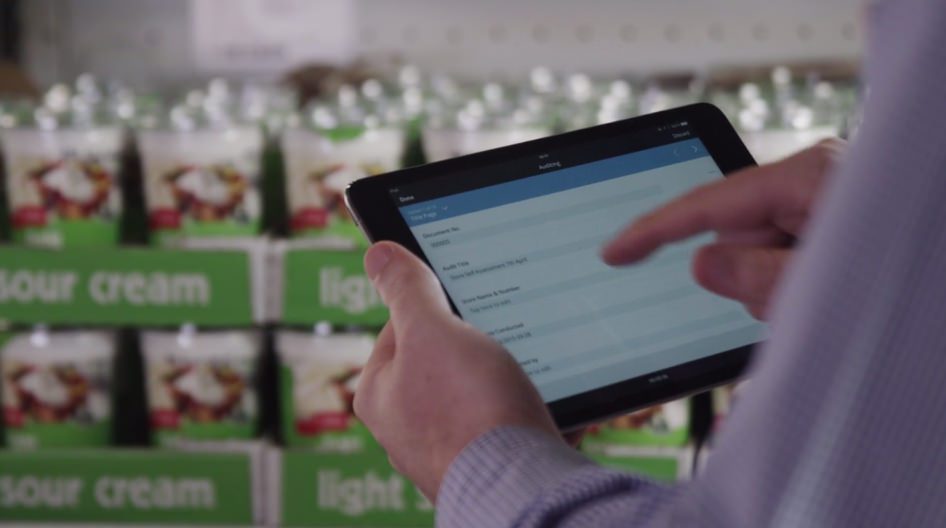

Failing to prepare is planning to fail. It’s never too late to introduce a better auditing process. Identify the pitfalls in your organization and create checklists to proactively change them. This will help you collect data and keep a check of your facility. You can stay on top of your organization’s auditing by having better visibility. See our reporting and insights resource for more information. A standardized auditing process will also get everyone in the organization into the habit of keeping standards at the forefront of their minds. It’s easy to fall into complacency or let repetitive tasks fall by the wayside. Having a formal auditing system in place will ensure each check is performed when it needs to be.

2. Keep accurate records

Looking to score some brownie points with your OSHA inspector right off the bat? Make sure your auditing records are readily available at the drop of a hat. By centralizing and digitizing your auditing system, all your audits are easily accessible so you can refer to those reports from anywhere, at anytime. The price of not keeping records is expensive. At the beginning of August this year, OSHA’s maximum penalty increased by 78%.

3. Conduct a walk-around

Work with the OSHA inspector and treat the visit as a learning opportunity for how to improve the standards of your organization. Take photos of everything the OSHA team photographs to document everything. The OSHA inspector will identify hazards as they see them and provide a list of what needs to be addressed. If you can action something immediately, then do so.

During the walk-around, audit chemical containers for compliance with OSHA’s Hazard Communication Standard—ensure GHS labeling includes the six required elements: pictograms, signal word, hazard and precautionary statements, product identifier, and supplier information.

4. Be proactive with the OSHA inspector

Similar to treating the OSHA visit as a learning opportunity, be proactive about any violations that they’re identifying. Ask for a copy of the complaint if there is one. Determine the purpose, scope and length of the investigation to know exactly where the fault lies. The inspector will ask for basic information about the facility, including:

- Number of employees

- Name of personnel in charge

- Contact information

- Type of work performed

They might also request files like injury and illness logs. You will be expected to produce them in a reasonable amount of time. Ensure you have your files and documents stored in a digital cloud, like Google Drive or Dropbox, or OneDrive. You do have a right to refuse entry to an OSHA inspector. However, OSHA can easily acquire either a warrant or subpoena.

5. Conduct a closing conference

You should arrange a time after the inspection ends to talk to the OSHA inspector. They will then summarize any hazards found. You can request summaries of sampling results for your reference. By being proactive throughout this process, you can address hazards fast before they become a larger incident. There are far too many incidents occurring in the construction industry. Technology is there to be used to enable you to keep your workplace a safe one. Don’t limit the closing conference to just yourself and the OSHA inspector either. Schedule some time with your team to communicate the findings of the inspection, positive or negative. This is a great opportunity to debrief with your team on what you’re all doing well and where you could improve. It’s also an ideal time to initiate new auditing processes if necessary.

6. Don’t wait to fix the hazards

OSHA has 6 months to file their citations but that certainly doesn’t mean you need to wait that long to address any hazards they identified. Safer and higher quality workplaces improve safety culture and benefit your bottom line. It’s up to you to ensure your workplace is operating safely. Being proactive and on the forefront will allow your employees to trust your process.

While compliance is often reactive, it doesn’t pay off in the long run. Compliance shouldn’t just be about avoiding being fined. Higher quality and safer work places are more productive for your employees. It will also benefit your brand and bottom line in the future. There are a number of checklists vital for your OSHA inspection.

Check out some more resources below:

Important Notice

The information contained in this article is general in nature and you should consider whether the information is appropriate to your specific needs. Legal and other matters referred to in this article are based on our interpretation of laws existing at the time and should not be relied on in place of professional advice. We are not responsible for the content of any site owned by a third party that may be linked to this article. SafetyCulture disclaims all liability (except for any liability which by law cannot be excluded) for any error, inaccuracy, or omission from the information contained in this article, any site linked to this article, and any loss or damage suffered by any person directly or indirectly through relying on this information.