Is Your Company On The Verge of a Deepwater Horizon Disaster?

Industry Trends | By | 30 Sep 2016 | 5 minute read

On April 20, 2010, an explosion rocked the Deepwater Horizon drilling rig in the Gulf of Mexico. The disaster killed 11 workers sending 5 million barrels of oil into the Gulf. The incident was a huge environmental catastrophe but also an incredible human disaster. When corners are cut, things go wrong. Hundreds of animals still suffer from the immense amount of oil spilt over 87 days. The economic damages rose to the billions as it affected the businesses and residents in the Gulf. With the release of the greatly anticipated Deepwater Horizon (2016) movie, it’s time to reflect on what the world can learn from such tragic disasters. Our environment is still reeling from the effects of the damage with widespread marsh erosion that is permanent in some places.

See the trailer below:

Here is what companies can learn from the Deepwater Horizon disaster:

1. Everyone pays attention when something goes wrong

It shouldn’t take a global disaster like the BP oil spill to remind us how important it is to work safely. Unfortunately everyone pays attention when something goes wrong. Time passes and other things happen, but allowing people to work safely is always important. Author and researcher Neil Swidey writes that workplace accidents tend to happen late in a project due to behavior called ‘normalization.’ If we’ve never suffered from an accident before, we can become complacent and fool ourselves into thinking nothing could go wrong. The wells that BP drilled worked most of the time. When you believe you’ve got a robust system in place, you tend to relax.

Crews battling the blaze after the explosion on the oil rig Deepwater Horizon. Photo: MCT

Crews battling the blaze after the explosion on the oil rig Deepwater Horizon. Photo: MCT2. The more risk, the more you should check

Preparing for a world where things only go right is a dangerous ideology to live by. It took the company 87 days to stop the leak. By then the damage was well and truly done. BP CEO, Tony Hayward infamously said that the spill was “relatively tiny” compared to the very big ocean. The more risk and people you have involved, the more you should check, re-check and re-check everything that is going on in great detail. The processes and mechanics BP were operating to drill the deep water well were incredibly complex. Even with multiple backups, failing to perform regular checks leaves plenty of room for human error. Which as Atul Gawande author of Checklist Manifesto describes – is fairly common. BP previously said the incident occurred due to the failure of eight different safety systems.

Here at SafetyCulture, we know first-hand how more checks equal safer workplaces. One of our customers, Level 10, performed 2.5 million man hours with zero injuries as they built one of the largest skyscrapers in San Francisco. That is phenomenal and means much more than saving costs. Another customer, Goldcorp know that the most important thing to down the mine everyday is the miner. And the most important thing to come out is the miner. That’s why they perform over 1,000 inspections every day.

3. Your backups need backups

The Deepwater Horizon disaster resulted from many human and technical errors in a risk-taking corporation. Greg McCormack, Director of Petroleum Extension Service at the University of Texas, states that the industry [and BP] had not developed an oil spill plan for a catastrophic failure at great depth. They moved into unchartered territory without any proven equipment or technology for when it didn’t succeed. They never thought about a contingency plan in case it went wrong, which it inevitably did.

4. Never underestimate the investment into safety

For years, the sustainability community praised BP as best-in-class. Under Hayward’s leadership, BP focused on cutting costs, avoiding talk about “green” initiatives in the media. Any individual who works in high-risk industries whether it be mining, chefs in restaurants, or truck drivers has a responsibility to perform their regular checks. Not only to invest in their own safety, but the safety of others. There is a well-known saying that ‘an ounce of regulation is worth many pounds of rectification.’ In 2014 a Federal judge ruled that BP made “profit-driven decisions” therefore leading to the well blow-out. By not investing in safe practices, BP spent more than $24 billion in spill-related expenses. They also agreed to pay $4 billion in penalties.

5. More than just your business relies on safety procedures

About 88,500 square miles of federal fishing water in the Gulf of Mexico was closed due to the spill. This area is where one-fifth of American seafood is caught commercially. The disaster vastly affected the residents of the Gulf of Mexico’s livelihood, causing businesses to shut down, costing in the billions. Fishermen and their support network were crippled by the oil spill and hasn’t fully recovered. No one knows how long the oil will impact the marine life, environment, and humans.

The non-economic costs of bad safety practices

1. Unsurprisingly BP was one of the two closely followed stories that year

The PEW research centre estimates that 59% of adult Americans were following the Gulf leak very closely out of a 14-week period. The BP Gulf story was the most covered news story, accounting for 22% of the newshole and generated 31% of cable news airtime during this period. Public interest remained high throughout. The only other story as closely followed as the Haiti earthquake in January, with 60% of adult Americans closely watching the news for this topic.

2. The public trusted news organizations more than the Federal Government and BP itself

In July 2010, 64% of those surveyed through PEW said they had a lot of trust in news organizations, and 64% said they had not much at all for BP.

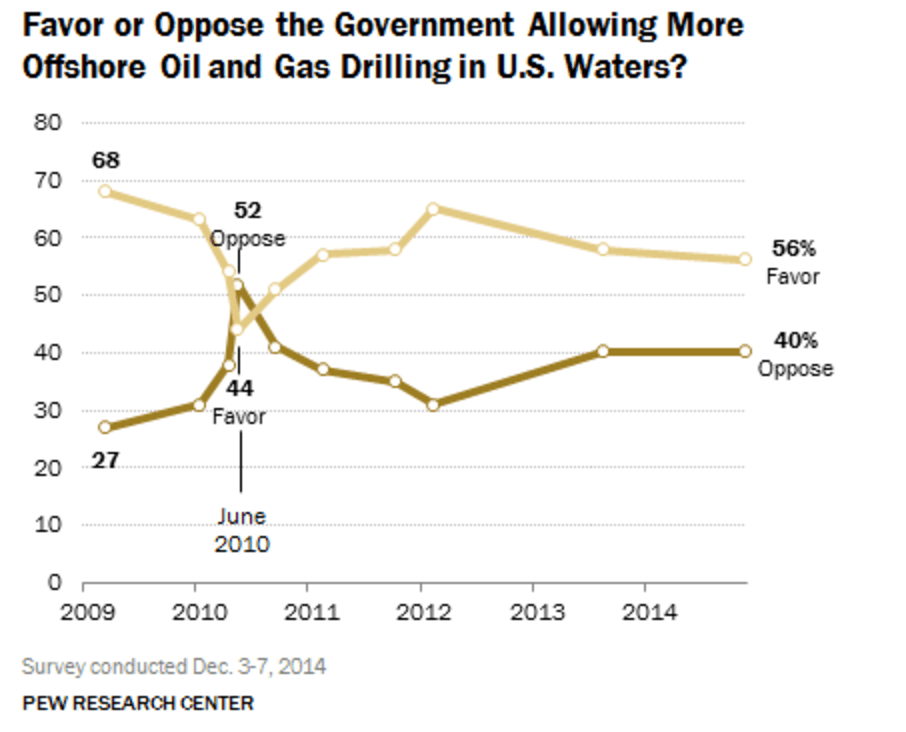

3. Support for offshore drilling plummeted

After the incident in 2010, Americans who favored more offshore drilling fell from 63% to 54%. By June, support dropped another 10%, with more people opposing drilling than favouring it. It seems like the idea of offshore drilling become more favourable the farther the incident was in history. The percentage of those who favoured the idea piqued in 2012 and has remained steady.

The PEW Research Center graph showing the drop in support for offshore oil and gas drilling in US waters.

The PEW Research Center graph showing the drop in support for offshore oil and gas drilling in US waters.4. 11 workers died and another 17 were seriously injured

In terms of how tragedies are measured, the Deepwater Horizon incident wasn’t to the scale of others. But the people that lost their lives had families – children, siblings, parents, and friends. Everybody deserves the opportunity to come home from work safely each day. This ideology is something we care deeply about at SafetyCulture and runs through every aspect of what we do.

5. This was one of the worst environment calamities caused by man on record

Tens of thousands of dolphins and whales were exposed to the oil, with a record high number of dolphin deaths. Nearly 100,000 birds from 93 species died. Centuries old deep-sea corals were smothered by oil. It is even believed the incident changed the entire ecosystem of the Gulf. 7,6000 large sea turtles and 160,000 baby ones died. Endangered sperm whales will take 21 years to recover after they suffered a 7% decline in their population.

A brown pelican coated in heavy oil tries to take flight Photo credit: Win McNamee/Getty Images

A brown pelican coated in heavy oil tries to take flight Photo credit: Win McNamee/Getty ImagesThe moral of the story: safety ROI

Health and safety professionals have an uphill battle to justify money spent on safety initiatives like training, technology or equipment. Calculating the cost of an injury is a difficult one, with several organizations attempting to estimate. A single fatal workplace injury can cost anywhere between 1.42 million to nearly $3 million. Safety isn’t just a ‘nice thing’ to do for your workers, it has economic benefits as well.

Important Notice

The information contained in this article is general in nature and you should consider whether the information is appropriate to your specific needs. Legal and other matters referred to in this article are based on our interpretation of laws existing at the time and should not be relied on in place of professional advice. We are not responsible for the content of any site owned by a third party that may be linked to this article. SafetyCulture disclaims all liability (except for any liability which by law cannot be excluded) for any error, inaccuracy, or omission from the information contained in this article, any site linked to this article, and any loss or damage suffered by any person directly or indirectly through relying on this information.