Physical asset management just got easier

SafetyCulture News | By | 1 May 2023 | 4 minute read

If you’ve been in business for a while, you probably know that the list of assets your business owns can quickly get out of hand. In fact, you may have tried and failed at keeping all of your asset information in a single spreadsheet. Physical asset management can often be time-consuming and hard to find what you’re looking for when you really need it.

At SafetyCulture, we’ve always believed the right information needs to flow to the right person at the right time, so they can make the best decisions to do their jobs. This principle doesn’t just apply to people, but also to places and things. That’s why we’ve introduced our latest feature, Assets, to the SafetyCulture platform.

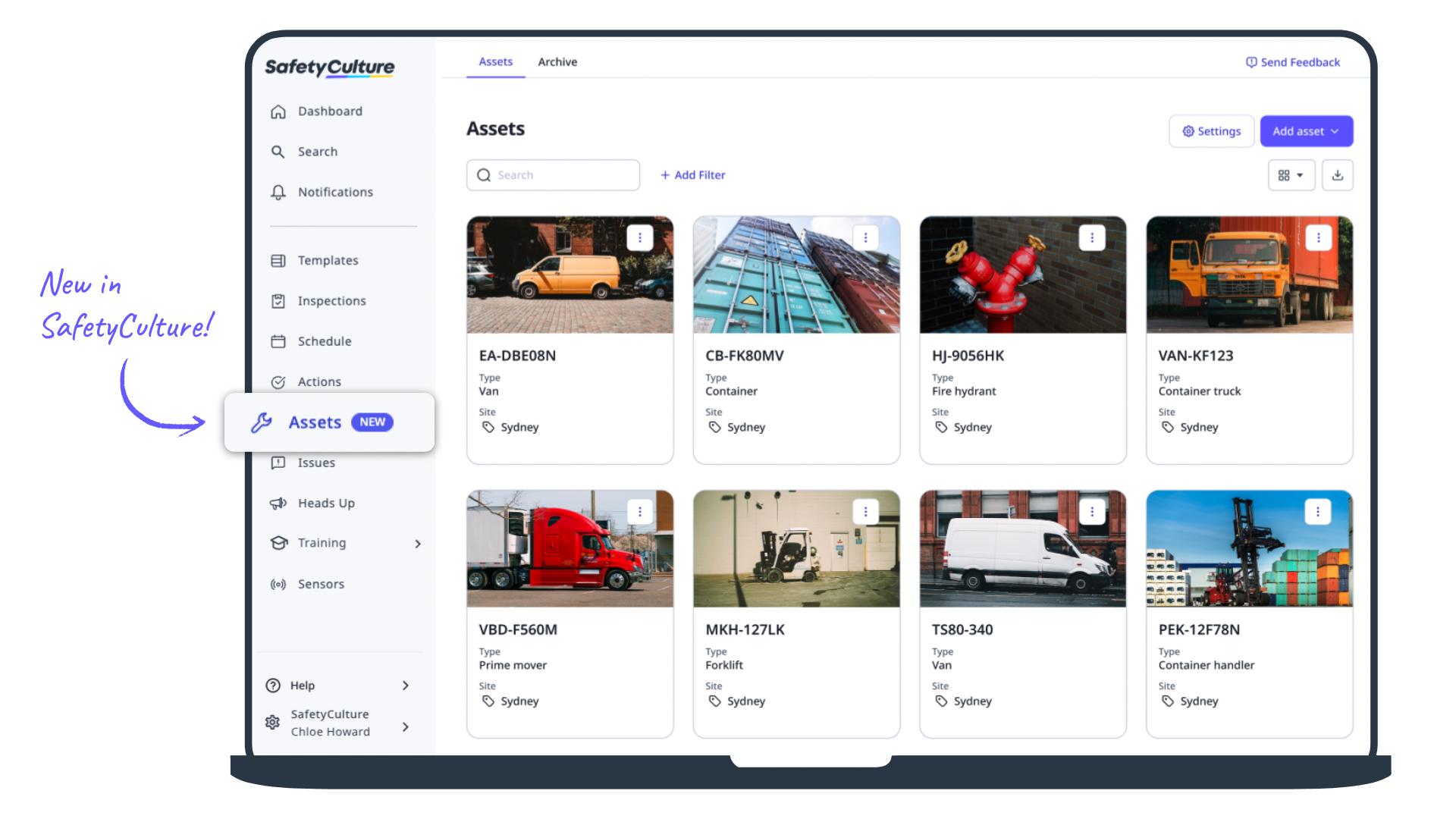

Now when we talk about assets we mean the physical things a business owns. Things like your vehicles and machinery, all the way through to property and equipment.

With our new Assets feature, you can create a comprehensive digital repository of all your assets and their associated data – important things like unique IDs, scheduled maintenance, service history, and their primary location.

We’ve also made it possible for you to generate unique QR codes for all of your assets using a free QR code generator, making it incredibly easy for anyone with a mobile device to retrieve asset information on the spot and even add new data on the go. Consider using a Uniqode’s QR Code Generator to keep asset details up to date without reprinting labels as information changes. It’s a game-changer that we hope will help revolutionize the way you and your teams access and manage important asset-related information.

Our customers drive our innovation

Over the years, SafetyCulture customers have creatively used our products to manage their assets, often resorting to hacks and workarounds. We recognized that this was a significant challenge and a problem that we wanted to help solve. Our goal was to unify and streamline asset management, before adding it to the SafetyCulture platform, along with all the other features. (Think of it like a pocket knife, where each tool has its own unique function.)

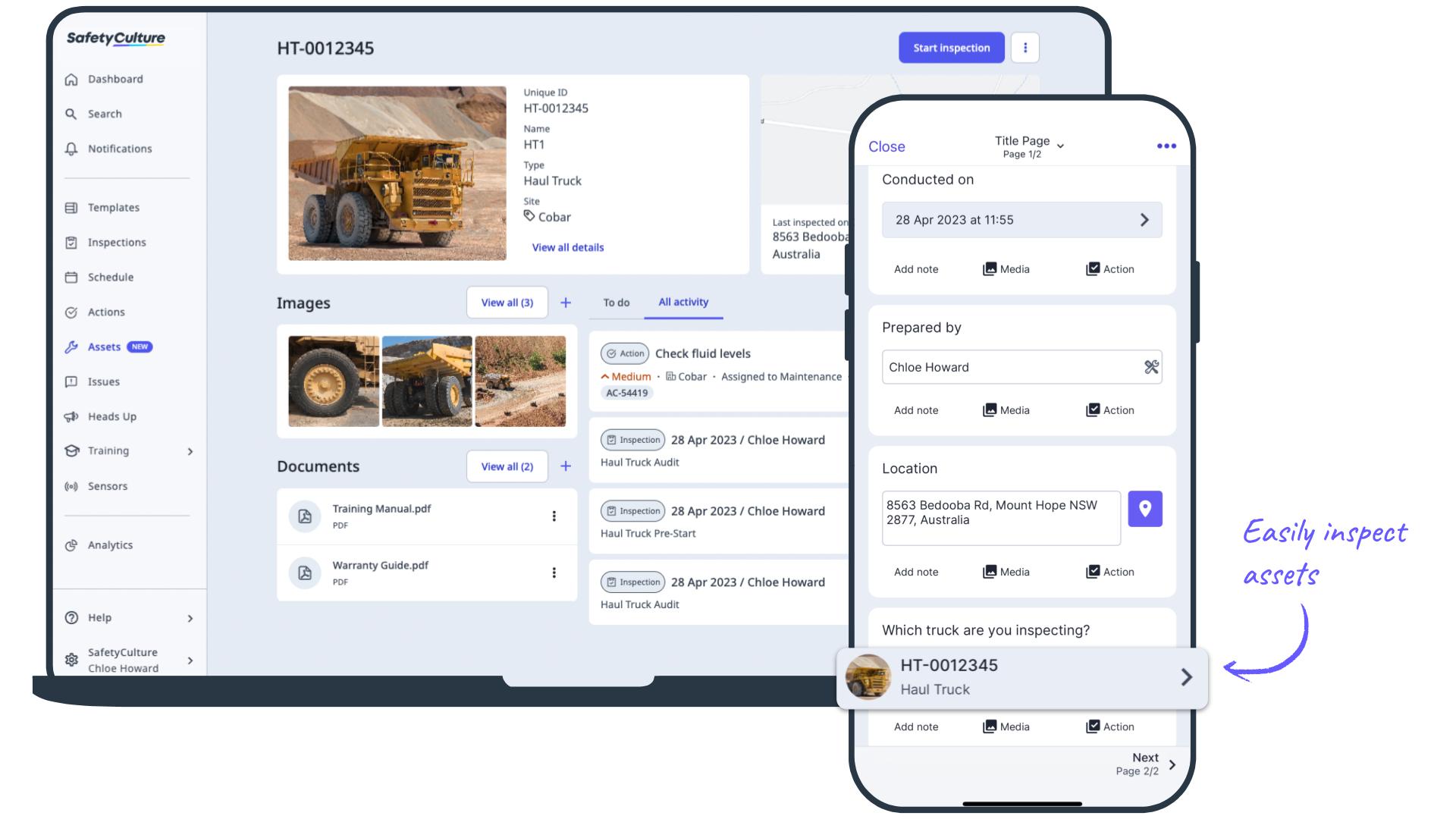

The great news is that the new Assets feature works with some of your favorite SafetyCulture features that you know and love. So you can do things like schedule and perform inspections on a particular asset, and even assign recurring or follow-up actions that are directly linked to a specific asset.

We’re saving you time and making life easier.

Assets – What is it good for? Absolutely everything

The possibilities are endless with Assets. Need to create a digital registry for each piece of machinery? That’s easy. Have to set up scheduled or one-off inspections for your cooling systems? It can also do that. What about arranging recurring or follow-up tasks to service your fleet of vehicles? Assets has got you sorted there too. And in combination with a resource for managing and marketing your business like Inside Advisor Pro, presenting comprehensive asset management in an easily navigable format is no longer the uphill struggle that it was in the past. Regardless of industry or size, businesses can significantly benefit from employing such resources.

Benefits and purpose of using Assets for physical asset management:

- Sharing information: Connect your frontline to the information they need to do their work.

- Preventative maintenance: Stay on top of maintenance activities and avoid unplanned downtime.

- Safety checks: Empower teams to perform in-depth safety, and pre-start inspections on assets.

- Quality control: Capture quality control data to ensure the reliability and performance of their assets.

- Maintaining compliance: View a secure, up-to-date audit trail of all inspections and tasks completed on their assets.

- Resource planning: Know where assets are, how often they’re inspected, and what areas need attention.

Car-subscription service Carbar uses Assets for preventative maintenance, as well as compliance and safety checks to keep its cars in top shape. “Carbar relies on SafetyCulture for our vehicle inspections, and we couldn’t be happier with the outcomes,” says Chris Malan, National Sales Operating Manager. “It’s helped boost our damage-related cost recovery by providing documented evidence to support charges.”

“Assets is especially good, as it lets us closely track each vehicle’s condition over time. We can swiftly search for a vehicle and access its inspection history to make faster decisions.”

– Chris Malan, National Sales Operations Manager, Carbar

Running like a well-oiled machine

Thanks to Assets, gone are the days of miscommunication and reactive repairs within teams. Teams on the ground can use Assets to feed real-time data directly to team leaders. This keeps things, like scheduled maintenance tasks, running smoothly and helps make sure they’re carried out on time without missing a beat. It’s better visibility, certainty, and connection for teams.

This new feature has already transformed the way people work at Hastings Deeling, which sells mining, construction, demolition, and earth-moving Cat equipment. “Assets has made my day-to-day so much easier by providing a digital solution to manage quality and compliance processes,” says Vaughan Kelly, Quality Assurance Coordinator. “I can seamlessly switch between assets, track service history, and focus on reviewing key customer-facing reports across our Rebuild Programs.”

“This high-level central management system has drastically improved efficiency, transparency and accountability.”

– Vaughan Kelly, Quality Assurance Coordinator, Hastings Deeling

On the horizon

Even though we’ve only just released the new Assets feature, we’ve already got our eye on the next improvement we can make. Our goal is to introduce real-time telemetry, which is essentially the process of collecting data from your assets, using sensors and other monitoring devices.

Think of it like a smartwatch that collects data about your heart rate counts steps and captures other health metrics, but instead of a watch, we’re talking about a device attached to a machine. By monitoring the performance of the asset and analyzing this data, it’s possible to identify patterns and potential issues before they become bigger problems, helping to prevent breakdowns and keeping things running smoothly. And because it’s automated, you’ll be able to do it without lifting a finger!

Important Notice

The information contained in this article is general in nature and you should consider whether the information is appropriate to your specific needs. Legal and other matters referred to in this article are based on our interpretation of laws existing at the time and should not be relied on in place of professional advice. We are not responsible for the content of any site owned by a third party that may be linked to this article. SafetyCulture disclaims all liability (except for any liability which by law cannot be excluded) for any error, inaccuracy, or omission from the information contained in this article, any site linked to this article, and any loss or damage suffered by any person directly or indirectly through relying on this information.