Use Digital Internal Audits for ISO 9001:2015

Checklist Best Practices | By | 27 Jul 2016 | 2 minute read

Are your current quality standards high enough?

A company’s entire reputation depends on the quality of the products and services that it delivers. With ISO 9001, the concept of standardized quality management allows companies to deliver consistent and reliable quality products and services across the globe. The previous ISO 9001:2008 was recently revised September of 2015. The ISO 9001:2015 is now the new standard quality management system.

The world business landscape has rapidly changed due to globalization, reduction in trade barriers, complex supply chains, reduction of tariffs, and moving towards service-based economies. To keep pace with these changes the ISO 9001:2015 addresses these new developments and focuses on achieving conformity of products and services to meet customer’s expectations.

By implementing the ISO 9001:2015 companies are able to make measureable improvements to their systems and processes to ultimately deliver good products and services. The process approach is an important part of ISO 9001, managing processes with “Plan Do Check Act” keeping risk-based thinking at the forefront. ISO 9001:2015 increases the confidence of customers in products they receive from suppliers which in turn brings many business benefits.

At the core of the ISO 9001:2015 are seven quality management principles:

- Customer Focus

- Leadership

- Engagement of People

- Process Approach

- Improvement

- Evident-based Decision Making

- Relationship Management

To be issued an ISO 9001 Compliance Certification a company must pass a third-party audit to ensure they meet the requirements. Third-party audits are usually a painstaking task. What’s the best route to a smooth external audit? Practice, practice, practice…internally! Tackling the hurdles of an audit process ahead of time and can save you time and money.

Implement Digital Internal Audits

Internal auditing is your best tool to evaluate your quality plan. Turning your existing internal auditing process into a digital one can automate tedious tasks like writing up paper reports and allow for tighter control over your processes. SafetyCulture delivers an app, iAuditor, to help you move to the digital world with your internal audits.

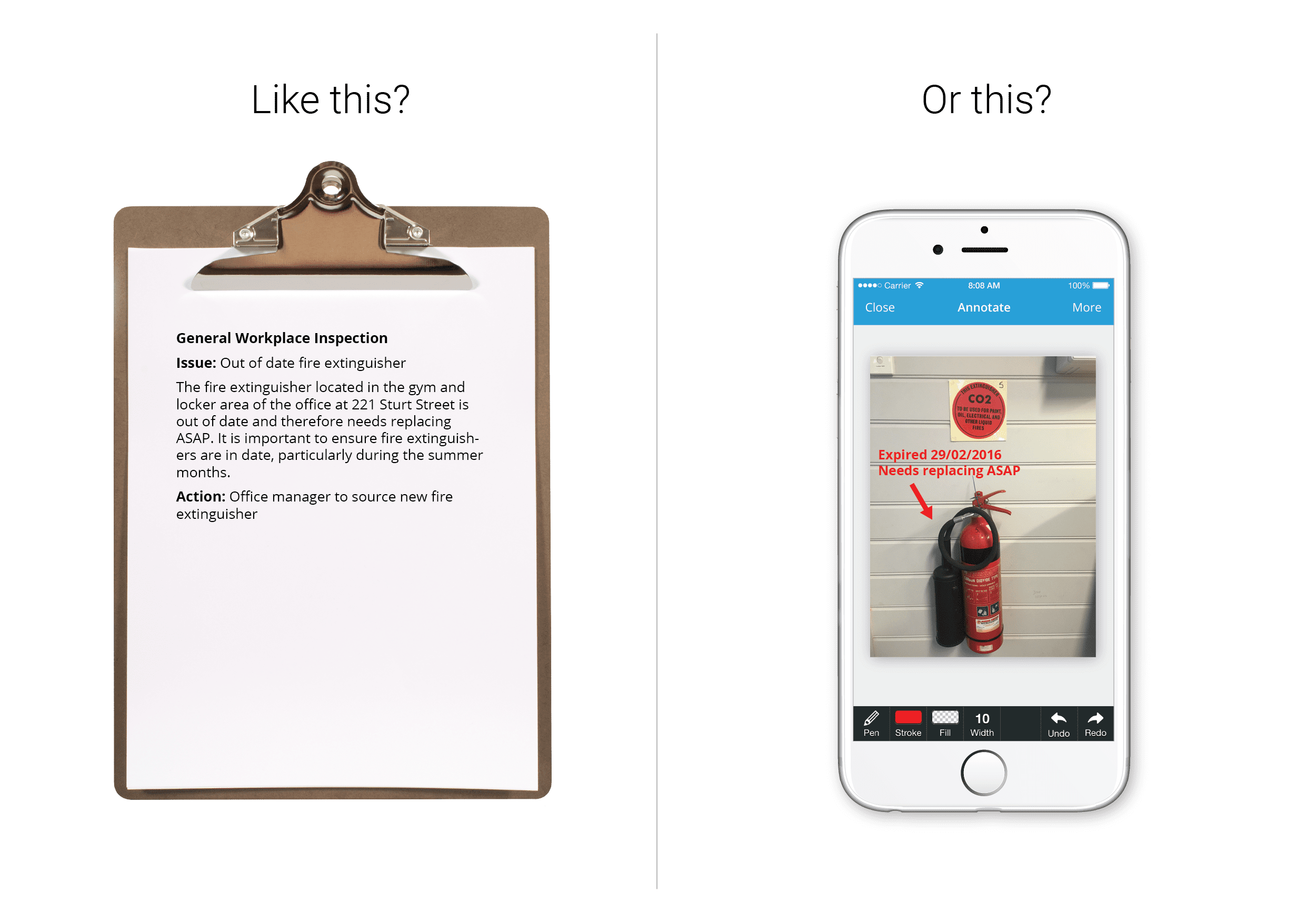

With the SafetyCulture iAuditor app you can streamline the auditing process for your internal auditors using digital pre-built template checklists for inspections at your facility. With standardized digital audits, your team can gauge the effectiveness of your ISO 9001 quality program and easily share their report findings with a touch of a button. Collecting evidence of compliance is made easy with the image capture feature in iAuditor. Snap a photo, draw and comment on it, attach and store it directly to the electronic audit report.

If internal auditors need access to manuals or other information during an inspection any required document can be attached to audit templates for easy reference. Once audits are completed using iAuditor all records are digitally stored in your SafetyCulture account to access whenever you need them. The digital audit data can be sorted and filtered with ease using the analytics tool for insight into your operations.

Need inspiration for your own ISO 9001 checklist? Check out this example template in our Public Library. You can also download it directly into your iAuditor app.

Get started today with a free SafetyCulture iAuditor account to start digitizing you quality inspections for better products and services to earn repeat business from your customers.

Important Notice

The information contained in this article is general in nature and you should consider whether the information is appropriate to your specific needs. Legal and other matters referred to in this article are based on our interpretation of laws existing at the time and should not be relied on in place of professional advice. We are not responsible for the content of any site owned by a third party that may be linked to this article. SafetyCulture disclaims all liability (except for any liability which by law cannot be excluded) for any error, inaccuracy, or omission from the information contained in this article, any site linked to this article, and any loss or damage suffered by any person directly or indirectly through relying on this information.