Boosting construction safety: How tech reduces risk and saves lives

World Of Work | By | 27 Sep 2024 | 4 minute read

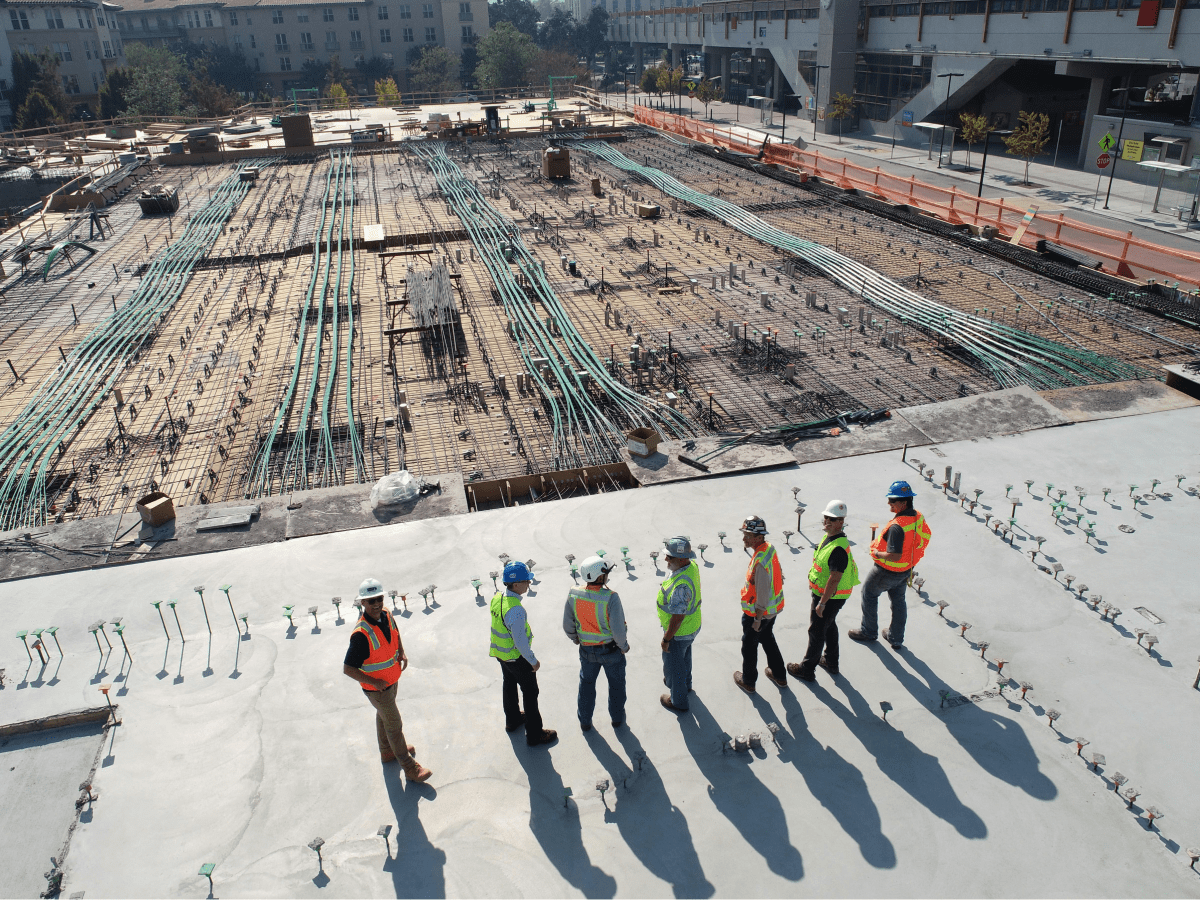

Working in construction is risky business. Even though safety has been in the spotlight for decades, injuries and fatalities continue to occur at alarming rates. The pressure is on to find better ways to protect workers while staying profitable, meeting customer demands, and upholding quality standards. Thankfully, new technologies offer practical solutions to help companies tackle these risks head-on and save lives on the job.

The real risks facing construction workers today

Construction is one of the most dangerous industries to work in, accounting for one in five workplace deaths. The most common causes? Falls, being stuck between or struck by objects, and electrocution. With so many hazards, staying safe requires more than a hard hat.

Workers often face the added pressure of tight deadlines, unclear safety rules, and outdated systems like spreadsheets and email, which leave them in the dark about real-time hazards.

Language barriers also present challenges, particularly on sites with diverse workforces. On top of that, around 30% of construction work is actually rework—leading to rushed tasks to meet project deadlines and a higher risk of accidents.

With so many risk factors, construction workers need better tools to protect them during the knockdown or rebuilding process. And employers must invest in the solutions that create safer environments.

The high cost of accidents

While worker safety is always the top priority, it’s not only the human toll that’s concerning. The financial cost of a single fatality can range from $1.4 million to $3 million, including legal, compensation, and other indirect costs. Worker safety is the top investment priority for EHS teams and is crucial to preventing these devastating losses. Construction workers face an array of risks that extend beyond typical safety hazards, such as legal implications when accidents occur. Personal injury lawyers can assist affected individuals in navigating the complexities of claims and securing fair compensation for injuries sustained on site. With significant sums often at stake, ensuring proper legal representation is crucial.

Making construction sites safer with technology

So, how can you tackle these risks? Digital platforms made for the frontline are a great place to start because they give real-time insights that can prevent hazards before they occur. SafetyCulture was built to solve daily frontline challenges and improve safety along the way.

Digital platforms can help track safety protocols, equipment, and teams in one place, from any device, in any language. They can help automate everyday tasks like inspections and audits so workers spend less time on paperwork and more time staying safe—and ensure nothing slips through the cracks.

Real-world example: Level 10’s success with pre-start checklists

Level 10 Construction implemented custom pre-task checklists using SafetyCulture to fix gaps in communication between the field and the office. Now, safety managers see real-time data and take action immediately. The result? 2.5 million man-hours without a single lost-time injury.

Empowering teams to act

Safety isn’t just a top-down responsibility—it’s about enabling everyone on the team to act quickly when hazards arise. With the right tool, frontline workers can make quick, informed decisions.

Using construction safety software to log hazards and incidents as soon as they happen allows on-the-spot issue resolution. Having a proactive approach like this will lead to fewer accidents and make a culture of continuous safety improvements the norm.

Real-world example: Coffey Testing achieves zero lost-time injuries

Before SafetyCulture, Coffey Testing’s hazard reports were lost in over 70 daily emails, and it took 2-3 weeks to address issues. Today, managers can set up workflows in just five minutes to capture critical information. With frontline workers able to report issues in real-time, Coffey Testing saw a 213% increase in reporting—and zero lost-time injuries. Read the story here.

Communication is critical to worker safety

Regular safety check-ins and training are also essential. Digital platforms allow site supervisors to run toolbox talks, track team progress, and ensure everyone is up-to-date on safety protocols. This reduces human error and keeps teams confident in their ability to manage risks.

Real-world example: Thermosash delivers effective training to a diverse workforce

Thermosash employs workers from 17 nationalities and struggles with language barriers in training. With SafetyCulture’s training platform and AI translation tools, they now deliver engaging courses in every worker’s native language, improving understanding, knowledge retention, and safety outcomes.

Addressing common hazards

Falls are the leading cause of construction fatalities. SafetyCulture’s customizable checklists help workers conduct job safety analyses and verify that safety measures like guardrails and safety harness are vital to prevent fall-related injuries in high-risk environments. These digital checklists are accessible on mobile devices, making it easier for teams to manage risks quickly and efficiently.

Beyond falls, construction workers also face significant danger from vehicles and moving objects. Platforms like SafetyCulture make it easy to spot hazards and can automate regular vehicle inspections and scheduled maintenance. This helps ensure machines are in safe working order and reduces the likelihood of construction injuries and fatal accidents on site.

The importance of offline capabilities

Many construction sites are in remote locations where internet access is limited. That’s why the best safety platforms offer offline capabilities. Workers can complete safety inspections, log hazards, and access protocols without being online. Once connected, the data syncs to the cloud, ensuring nothing is lost. This feature is essential for teams in high-risk, isolated areas where real-time safety management is still crucial.

SafetyCulture’s lone worker solution takes this further by keeping lone workers connected to their teams, regardless of location. In industries like construction, where workers are frequently alone in high-risk situations, it provides real-time safety monitoring and alerts, ensuring that workers are never truly isolated.

Safety and compliance made easy

Navigating the complexities of safety regulations can be daunting, particularly in high-risk industries like construction. SafetyCulture simplifies compliance by centralizing safety documentation, inspections, and incident reports in one easy-to-access location. No matter where you’re located, the platform makes it simple to meet safety standards, reduce risks, and protect workers.

In a sector where lives are on the line, the need for a comprehensive and accessible safety solution has never been greater. SafetyCulture empowers construction companies to take control of their safety processes, minimize risks, and create safer worksites for all.

Read more construction safety success stories:

- ArcelorMittal Construction improved employee safety at 43 production sites

- Tremco created a safer workplace with visibility into the frontline

- Schindler logs 1,200 hazards a year (up from 20) and achieves their safest year

Important Notice

The information contained in this article is general in nature and you should consider whether the information is appropriate to your specific needs. Legal and other matters referred to in this article are based on our interpretation of laws existing at the time and should not be relied on in place of professional advice. We are not responsible for the content of any site owned by a third party that may be linked to this article. SafetyCulture disclaims all liability (except for any liability which by law cannot be excluded) for any error, inaccuracy, or omission from the information contained in this article, any site linked to this article, and any loss or damage suffered by any person directly or indirectly through relying on this information.