Customer Stories: Keeping food quality fresh with SafetyCulture

Customer Stories | By | 21 Jul 2023 | 4 minute read

When it comes to feeding the masses, there’s a lot to keep track of. For three food industry giants – Coles, Marley Spoon, and The Dinner Ladies – the recipe for getting it right shares the same secret ingredient… SafetyCulture.

Coles Supermarket

Improved efficiency is in the bag

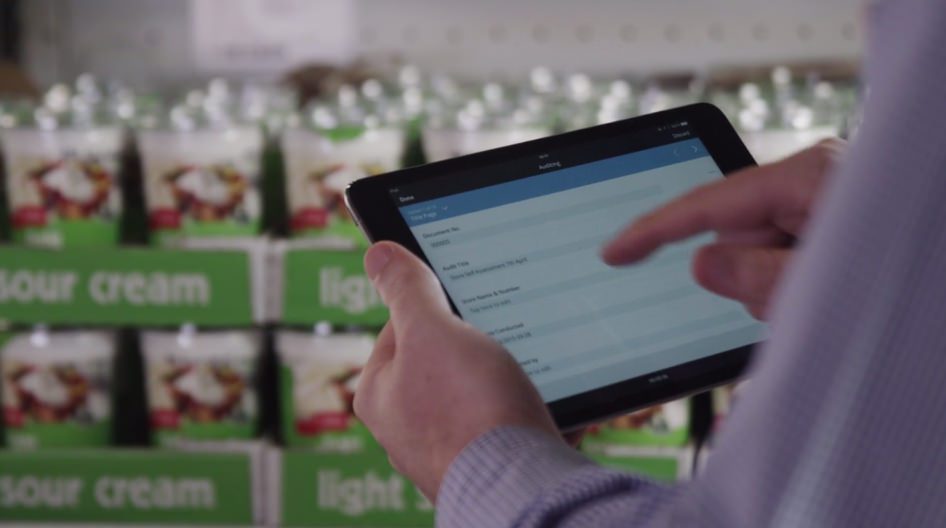

As one of the leading supermarkets in Australia, Coles Supermarket is known for its high-quality goods and top-notch shopping experience. SafetyCulture helps Coles maintain its high standards and stay competitive in the industry.

The SafetyCulture platform’s drag-and-drop template builder makes it easy to convert paper checklists or spreadsheets into smart inspection forms. For businesses in the food service industry, compliance forms and safety monitoring systems, like HACCP, can be created in a matter of minutes.

The switch from paper-based to digital audits has increased efficiency and process standardization across all of Coles’ retail locations. The monthly, weekly, and daily audits that all store managers conduct now provide management with live visibility over the entire organization. Insights from the data collected within the platform make it easy to identify trends, spot areas of non-compliance, and hold their third-party partners accountable.

Marley Spoon

Maintaining quality standards with grade-A data

A pioneer in using data to elevate food safety and quality standards, Marley Spoon Australia delivers thousands of fresh, ready-to-cook meals to their customers every single week. Tracking trends is critical for Marley Spoon’s success. They trust the SafetyCulture platform and SafetyCulture Sensors to ensure everything – from the food they deliver to the suppliers they work with – meets their top-notch standards.

In the journey to maintain food integrity from farm to table, adopting Good Manufacturing Practices (GMP) approved methods for cleaning and sanitizing produce is essential. As companies strive for excellence in food safety, leveraging advanced technologies ensures compliance with health standards while enhancing product quality.

Performing audits and inspections in the platform saves time, reduces errors and improves visibility into processes across the business. With all this data at their fingertips, Marley Spoon can identify any areas for improvement and confidently take action. Trends in the completion times for routine audits help their team accurately allocate resources, and any unusual patterns in supplier non-conformance reports are easier to recognize and address.

“We have visibility into everything because of the data we capture in the SafetyCulture platform. If there’s a threshold exception or process that needs improving, all we have to do is drill down and we’ll find it,” says Sofia Dias, Food Safety and Quality Assurance Manager at Marley Spoon.

While exploring innovative ways to maintain food quality and safety, companies might also consider the impact of their meal kits on customer satisfaction. Recognizing the most 5-star meal kits with HelloFresh not only highlights excellence in fresh, quality produce but aligns well with the ethos of ensuring customer trust through high standards.

The Dinner Ladies

Digitizing recipe production for delicious replication

Committed to providing tasty, market-fresh, and fuss-free food, The Dinner Ladies is a meal-delivery service that supplies more than 12,000 delicious dinners a day across Australia. Building a culinary empire isn’t easy, which is why founders Sophie Gilliatt and Katherine Westwood rely on SafetyCulture to automate their safety systems and digitize their processes.

Paper recipes and forms may suffice in smaller-sized kitchens, but The Dinner Ladies knew it was inefficient when cooking at a large scale. “Producing lasagne is very different to producing pumpkin soup. There are different steps and processes that need to be accounted for. With SafetyCulture we can design our templates in the platform to match the dish easily, so someone isn’t sifting through a logbook that covers every single process and production we do,” Katherine says.

With accurate controls and greater awareness of what’s going on in the kitchen, they were able to perfect their recipes and realize improvement in product quality as well. Equipped with the right tools, the team at The Dinner Ladies has the flexibility to adapt the SafetyCulture platform to their business needs, whatever they might be.

Other ways to use SafetyCulture in the food industry

Reducing food waste with temperature sensors

Manual routine cold-room checks to monitor and maintain temperature levels waste valuable human resources. But if storage temperatures aren’t monitored, businesses risk large-scale inventory loss, and costly recalls – not to mention, the risk of making customers sick with food poisoning.

SafetyCulture Sensors automate the temperature monitoring process to help Marley Spoon and The Dinner Ladies keep their cool. Temperature sensors, humidity sensors, and Bluetooth-enabled temperature probes allow them to oversee temperature controls with absolute precision and certainty. Tracking these critical parameters in real-time has reduced staffing hours and increased peace of mind.

Getting started with sensors is a piece of cake. The easy-to-install hardware has no IT requirements — just unbox the temperature sensors and stick them in the fridge!

Simplifying tech rollout and implementation

Coles found that rolling the SafetyCulture platform out to their 800+ stores was surprisingly easy and only took a matter of weeks. For any supermarket, managing food safety ultimately lies in the hands of store employees and requires an intuitive tool that empowers them. “We had to deliver a solution that resonates beyond the store manager,” Simon McBurney, Senior Delivery Analyst at Coles, says. “We believe we’ve hit the mark with the SafetyCulture platform, helping them manage the shop and ultimately giving customers a shop they can trust.”

Tech adoption in the workplace can be tricky to manage, but we’ve tried to make it as easy as possible for people to use SafetyCulture. “If you know how to use Facebook, you know how to use SafetyCulture,” Aarron Natale, Head of IT at The Dinner Ladies, says. “With entry-level training, staff were able to take the tool and run with it. We could do it all ourselves instead of sending off a request and waiting for weeks for it to happen.”

The SafetyCulture platform not only allows these food industry giants to operate efficiently, it also helps them to adhere to food safety legislation and laws that are vital to creating a safe environment. For Marley Spoon, the successful implementation of SafetyCulture across Australia is the driving force behind their decision to roll out the SafetyCulture platform across every facility around the globe. Consistent standards for safety, quality, and audits will mean fresh meals for customers everywhere.

Interested to learn more about their stories? Read these…

Important Notice

The information contained in this article is general in nature and you should consider whether the information is appropriate to your specific needs. Legal and other matters referred to in this article are based on our interpretation of laws existing at the time and should not be relied on in place of professional advice. We are not responsible for the content of any site owned by a third party that may be linked to this article. SafetyCulture disclaims all liability (except for any liability which by law cannot be excluded) for any error, inaccuracy, or omission from the information contained in this article, any site linked to this article, and any loss or damage suffered by any person directly or indirectly through relying on this information.